Monel K500 (UNS N05500) is an age harden-able, nickel- copper based alloy which combines excellent corrosion resistance and high strength. K500 is used extensively in the marine industry, in both military and commercial applications. It is also commonly used by the power generation, chemical processing, oil and gas, pulp and paper sectors as well. Due to its combination of high strength and corrosion resistance, K500 is extensively used for critical fastening applications where failure is not an option.

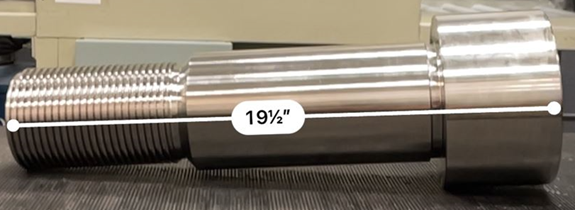

Vegas Fastener Manufacturing is a domestic fastener manufacturer, specializing in hot forging of corrosion resistant and high strength critical application fasteners for both military and commercial applications. Vegas has years of experience forging and machining K500 fasteners to both standard and custom, per print specifications. We have the capability to fabricate parts from ¼” through 8” in diameter in almost any head style and configuration, from hex cap screws, socket cap screws, full thread studs, 12-point flange bolts and all types of nuts as well. When manufacturing highly engineered custom fasteners, flexibility is critical. Vegas Fastener Manufacturing can offer competitive options on quantities from 50 to 25,000+ pieces with lead times that can be tailored to meet the customer’s requirements.

When looking for a source for domestically manufactured fasteners in Monel K500 or any other corrosion resistant, high strength or high temperature alloy such as Alloy 718, A-286, Waspaloy, 17-4PH, Alloy 625 and others, Vegas Fastener can deliver the highest quality fasteners at a competitive cost with flexible lead times